Tides, Trials & Vials – Pharma in Flux

Galenisys Newsletter : August 2025

Table of Contents

By Tony Dunford

Editor

-

TALES FROM FARAWAY PHARMA

“Dangerous Questions”

By Steve Biddulph -

THE PHARMA TARIFF TIDE

The Editor -

THE VALUABLE PROCESS OF FREEZE DRYING

By Richard van Duyse -

VACCINES, GOOD & BAD NEWS

By The Editor

TALES FROM FARAWAY PHARMA

By Steve Biddulph

Fellow of Royal Society of Biology. Board level pharma experience. QSM and Aseptic Manufacturing & Control Expertise. Galenisys Managing Director.

Part 2 Dangerous Questions.

(the 2nd of a series of experiences & lessons Steve has accumulated over the decades – The Editor)

As my colleagues and I moved around Latin America, we met a wide variety of people who owned pharmaceutical companies, or who worked in them.

In Colombia, we worked for 4 weeks in identifying and then auditing any companies that held contracts for manufacture of licences for our products. This took two of us to Cali to audit the Colombian manufacturer of our stomach acid neutralising liquid product.

We started with the water system. The potable water and purified water storage tanks were both crumpled scrap due to having been installed without air breaks for the tanks. (If “steamed out” any unvented tank can collapse on cooling unless built to withstand full vacuum - Editor).

The issue was ongoing in the law courts with the supplier but, at the time of the audit, there was no purified water system.

The water was being taken from the river next to the site directly into product formulation! A look, at the microbiological monitoring results both for formulation water and product showed that colonies were far too numerous to count despite dilution to 5 log. This was true for general counts, and for counts on media specific for Enterobacteriaceae and Pseudomonadaceae.

At the end of the audit, I presented the result to the site director and company owner. I told them that they would have to cease manufacture until the water system was back in operation and counts were once again (hopefully) at an acceptable level with no undesirable organisms present. I pointed out that the product was intended to relieve gastric discomfort and not to cause it.

The site director looked at me with his Cuban heel boots on his desk and a cigarillo in its holder in his hand and said, “Do you know where you are?”.

My colleague whispered to me on our way out “I think that was a threat !!” Luckily we made it back to Bogota and Europe with no problems.

I’m sure things are a lot better in Colombia now, but I am still wary of dark figures in the street carrying violin cases.

Steve Biddulph

THE PHARMA TARIFF TIDE

The Editor

As they sit by the seaside this vacation season, our readers can reflect on the ebb and flow of the tides. It's a reminder of how things go up and down.

So it is with prospective taxes on pharma imports into the USA. Having previously suggested the tariffs on pharmaceuticals could hit 200% earlier this year; the current occupant of the White House stated on the 15th of July that America would “start off with a low tariff” on pharmaceuticals, “probably before the end of the month” (of July); before making it a “very high tariff” wall within a year or so.

The potential changes in pharmaceutical tariffs, however, are quite different for different countries. Singapore, for example, would be hard hit. Its exports of vaccines & active ingredients to the USA worth approximately $10 billion, are high value-added.

India, whose exports to the USA have the same value, would be hit a lot less hard however since these are largely generic products, with lower value added.

Barclays Bank have calculated that Singapore would face an effective % tariff hike 6 times as steep as India because of this bigger domestic value added. (Note however, this study was before the 15th of July announcement by Mr. Trump).

Nevertheless, Singapore's top trade negotiator has made winning concessions on pharma exports his top priority, when he gets a chance to parley.

By the same measure exports to the US from the euro area would be hit approximately twice as hard as Indian ones.

The reaction of market analysts and professional stock traders to such ebbs & flows is increasingly to shrug their shoulders. But whatever the ebbs and flows, some clients advise us that the tariff uncertainty continues to postpone some investment decisions and or pause some existing projects in our industry.

The Editor

THE VALUABLE PROCESS OF FREEZE DRYING

Why it’s so useful & how it is done

By Richard van Duyse

Experienced international vaccine industry consultant. Specialized in project & operational management, facility design, start-ups, & technology transfers. Bachelor of Applied Science (B.Sc.).

Lyophilization, or "freeze-drying", is a really important process in the pharmaceutical world. It is used to preserve delicate products like vaccines, proteins, and other biologics by removing water while keeping their structure intact.

For vaccines the freeze-drying process has the following key advantages,

- Longer shelf life - Freeze-dried vaccines can be stored much longer than liquid vaccines, often for years at refrigerator temperatures or even at room temperature, depending on the vaccine. This is especially useful in countries where “cold chains” are difficult to guarantee.

- Better stability - In liquid form, vaccines are often sensitive to heat, freezing, or temperature fluctuations. However, when freeze-dried, vaccines are less sensitive & thus less expensive to transport & store safely.

- Retention of efficacy - Some vaccines lose their potency quickly in liquid form. Freeze-drying keeps the active ingredients stable and effective until use.

- Ease of use on site - Freeze-dried vaccines are reconstituted with a liquid (usually sterile saline or water) just before administration. This "preparation at the point of use”, is particularly useful in, field situations or mobile clinics.

- Reduced risk of contamination or degradation - In a dry form, vaccines are less susceptible to microbial growth or chemical degradation.

Well-known & valuable freeze-dried vaccines are the BCG vaccine against tuberculosis, BMR vaccine against Mumps, Measles and Rubella diseases, and Rabies vaccine.

Selecting the appropriate container and closure system is vital, as freeze-dried products need this long shelf life. To maintain integrity, stability, and sterility for products the system must:

- Be an effective gas barrier.

- Prevent Moisture ingress, since these products are susceptible to moisture absorption, which can compromise their stability and quality

- Preserve the sterility and prevent product contamination

- Be robust enough to maintain integrity throughout the product's shelf life.

- And be compatible with the freeze-dried product and process.

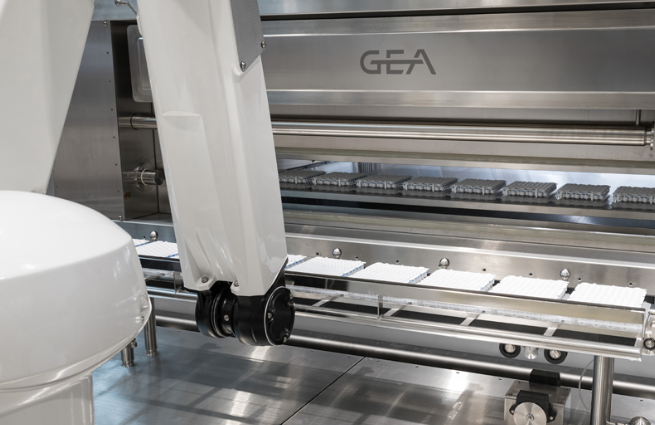

Freeze drying is a step in the batch process between filling and capping of the vials. Whereas the actual freeze-drying step usually takes between 1 & 7 days depending on the product, the whole process consists of:

- Pre-treatment / Formulation i.e. “batch make up”

- Filling & loading the filled vials into the Freeze Dryer.

- Freezing (Thermal Treatment) at below atmospheric pressure and the eutectic temperature (the point being the lowest temperature at which the liquid phase is present).

- Primary Drying (Sublimation) under Vacuum

- Secondary Drying (Desorption) under Vacuum

- Pre-aeration and stoppering (for product in vials) under Partial Vacuum or inert gas, followed by aeration.

- Removal of dried product from the Freeze Dryer

The whole process of filling from vial cleaning & filling through freeze drying to capping, requires high area classified conditions.

The process has the following product benefits:

- Stability of active components (antigens, proteins, viral particles) is maintained when done correctly.

- Protection against denaturation, hydrolysis, and oxidation, processes that occur in liquid vaccines.

- No microbial growth in dry form providing improved microbial safety.

- Possibility of longer storage of sensitive vaccines (e.g., mRNA, protein vaccines).

However, product integrity is threatened if:

- Freezing is too quick or too slow since ice crystals can damage cells or proteins.

- Denaturation of proteins occurs because of lost immunogenic activity.

- Excipients (such as stabilizers) are missing or unsuitable.

- Leaking bottles or poor seals allow moisture ingress & product degradation.

Cryo-protectors or lyo-protectors are often added (e.g. sucrose, trehalose, mannitol), which stabilize the structure during freeze-drying.

In summary, this process is extremely valuable, but also demanding, and in need of careful validation to be successful.

VACCINES, GOOD & BAD NEWS

The Editor

Members of the Filovirus family have caused deadly epidemics in a number of African countries.

Ebolavirus Zaire killed more than 11,000 people in West Africa between 2014 and 2016. More recently, there was a deadly outbreak of the Marburg virus in Tanzania, Rwanda and Equatorial Guinea. Health services in the continent also have to keep a lookout for the fatal Sudan Ebolavirus.

Now CEPI and EU Horizon Europe are to jointly fund a project led by Denmark’s AdaptVac to design and test a new all-in-one shot vaccine that could offer broad protection against several filoviruses.

Researchers will use state-of-the-art AI technology to design potential substances that in vaccines that elicit an immune response against multiple filoviruses, & assess the best for later clinical testing.

A byproduct of this research will be more data & scientific knowledge about the filovirus family vaccines, suspected of including ‘Disease X’—an as-yet-unidentified member which the experts fear could cause another pandemic. “Common denominator knowledge” about filoviruses could reduce vaccine development lead-time in this eventuality.

Other bad news is the continuing anti vaxxing stance of the US Secretary of Health (even whilst measles progresses).

ADVANCES WITH VACCINES

However elsewhere there is good vaccine news.

Nordic’s MVA-BN mpox vaccination trial in DRC as part of a CEPI-funded clinical trial.

Amid the ongoing mpox emergency, pregnant women, & infants in the DRC are receiving mpox vaccinations as part of a CEPI-funded clinical trial. It will evaluate the safety and immunogenicity of Bavarian Nordic’s MVA-BN® mpox vaccine.

Oxford's Nipah vaccine gets PRIME status from the EMA.

The University of Oxford's Nipah vaccine candidate has got PRIME status from the EMA. This means earlier and closer discussion with regulators to accelerate the vaccine’s development will be likely.

The Editor